Hot rodding innovation borrowed heavily from the aircraft industry of the 1940s and 1950s where strength and weight savings were paramount. One common practice to reduce weight was to drill holes to remove unnecessary material while flaring the edge to help maintain strength.

Early on in hot rodding days, you would see a lot of sheet metal cut out to save weight on the track. One of the most famous uses came from Pontiac on their ‘Swiss Cheese’ ’63 Catalina drag cars that had hundreds of holes drilled throughout the chassis to save weight. Prior to that however, the use of punch and flares were found on serious hot rods and have since become more of a cool visual detail found on everything from seat brackets and interior panels to radiator supports.

We’ve always liked these kinds of details but are far from talented when it comes to sheet metal working. We were perusing the web one day and came across the tools to create consistent punch and flares that looked like something even we could handle. We called up Mittler Bros. Machine and Tool for more info.

Mittler offers a number of automotive and aircraft punch/flare kits ranging in dies from 1” – 3” in diameter. Not only are these handy for aesthetics, but the dies are also ideal for creating an instrument panel (each die can be used without the flare for a perfect circle).

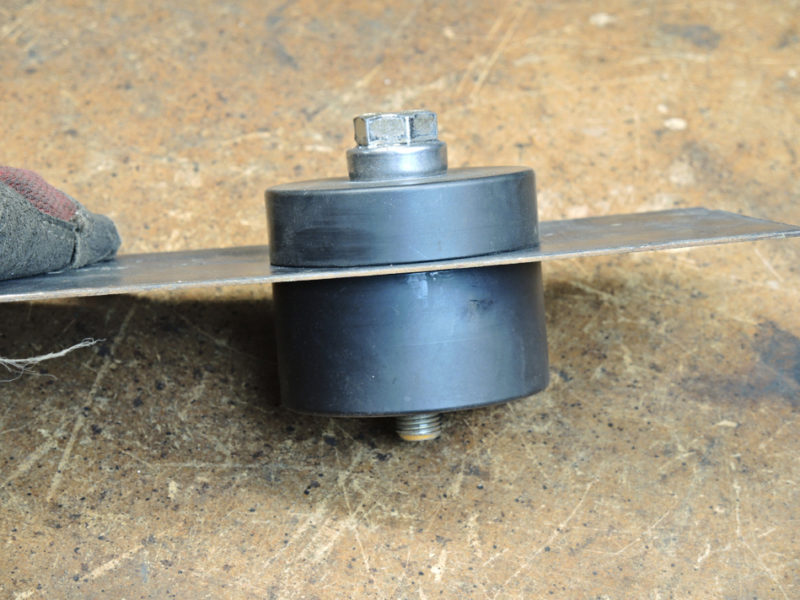

The dies are available individually or as a complete kit if you’re getting really serious. Also, thanks to the bolt and threaded lower die, no press is needed. (Though if you were doing a large number of holes a press would be handy.)

The punch/flare die is heavy duty and will last you a long time punching holes in everything in your garage. Once the hole is punched, the top die follows with a 45° flare with a length of about .25” for a smooth, finished transition. As far as material, the dies are designed for use with metals ranging from .023”-.065”.

The end result will make you look like a pro and we can see how easy it is to get into more sheet metal tricks. We already have our eyes on the punch/bead dies, or their Jamey Jordan series oval and even triangle punch/flare kits. Thanks Mittler Bros.!