1987 Buick Grand National – Buford

FollowVehicle Quick Facts

Profile ID: 15163

Year: 1987

Make: Buick

Model: Grand National

Markets: Classic & Antique, Muscle Car, Performance, Racing, Resto-Mod

Vehicle Type: American

Contact: Andrew Scott

![]()

Vehicle Story

This 1987 Buick Grand National is a survivor. Unrestored and driven hard.

The owner came across this vehicle in January of 2000. A friend of a friend owned it, and when he decided he was done with the vehicle, his children started fighting over it. Not wanting to deal with the drama, he sold it to a local dealership and told his kids, "If you want it so much, go buy it." Except the owner got there first. As the proud third owner, he drove the vehicle home on cold January day with just 16,271 miles on the odometer. It was bone stock save for a CB antenna. Today, with over 80,000 miles, this car has been completely transformed.

The first twelve years of ownership were largely uneventful. A few simple bolt-ons, custom chips, and 16" wheels went on. These years were mostly spent taking the vehicle to car shows, with an occasional outing to the drag strip or an autocross just for giggles. It was wallowy and difficult to control in autocross situations. On the drag strip, the bone stock motor made it to a 13.07 @ 104mph with a chip.

After the owner sold his primary autocross car in 2012, he turned his attention to his remaining toy. Uprated springs and Bilstein shocks improved the handling, but it still chewed up tires, and the strict SCCA rulebase made running it in autocrosses problematic. Altering the boost at the time bumped the car all the way into Street Modified, a class dominated by lightweight imports with exotic powertrains and no street manners.

Then in 2014, the world opened up. The SCCA Introduced the Classic American Muscle class. Finally, a place to play that suited the vehicle! A larger turbocharger and conversion to E-85 resulted in a lot more power. In August of that year, the car blew a head gasket at Lucas Oil Raceway during a run in which it coasted across the finish line at 111mph, a new personal best. That failure prompted an engine-out service and the beginning of serious work transforming the car. This build has been a steady process of identifying and fixing problems in a methodical way, not shotgun blasting parts at the vehicle and wondering why it was being beaten despite the expense.

During the winter of 2017-2018, the engine was rebuilt by the owner, in concert with Boost Crew Motorsports. The engine was stroked to 4.1 liters with a 4340 forged steel crankshaft, Molnar forged connecting rods, and Carillo forged pistons. A small-base-circle Comp Cams roller cam with 212/212 duration at 0.050" applies pressure to Earson roller lifters. Smith Brothers provided the custom heavy duty pushrods, and TA Performance supplied the heavy duty shaft mount rocker set. Everyhing is held together using ARP fasteners. Fuel is supplied by a Racetronix 450LPH pump feeding 60lb injectors.

The ECM is a TurboTweak ECUGN, which is an MS3Pro based system with some unique features tailored directly to the Turbo Buick. The ECUGN allowed the owner to implement traction control, close loop boost control with overboost protection, and add sensors to monitor all the vital drivetrain fluids that the original ECM couldn't monitor (engine oil temp, oil pressure, transmission temp and pressure)

The ignition is a Bob Bailey TR6 module with uprated coils firing through Taylor wires and NKG spark plugs.

A Tial blow off valve was fitted after data acquisition at the 2016 Wilmington Champ tour showed the car was taking upwards of 1.7 seconds to build boost after a throttle lift. Air reversion was stalling the compressor. After the valve was fitted, re-spool was reduced to less than half a second after a throttle lift. Driveability dramatically improved.

The OE rubber hose vacuum lines were replaced with a push-loc fitting kit from Cruz Performance to eliminate problems with vacuum lines blowing off their fittings under boost.

The cooling system was upgraded with a huge 3" core aluminum radiator from GN1 Performance, along with dual 1300 cfm fans. A custom PCV system using two catch cans and industrial strength check valves had to be engineered to properly evacuate crankcase gasses without allowing manifold pressure to pressurize the crankcase under boost. The system works so well, the car is likely one of few Buick V6 engines in the nation that does not leak. A Deral power steering cooler helps keep the reservoir from overflowing during heavy use. An enormous transmission and engine oil coolers also are mounted ahead of the radiator, the area behind the grill has been boxed in with sheet metal replacing the factory rubber flaps.

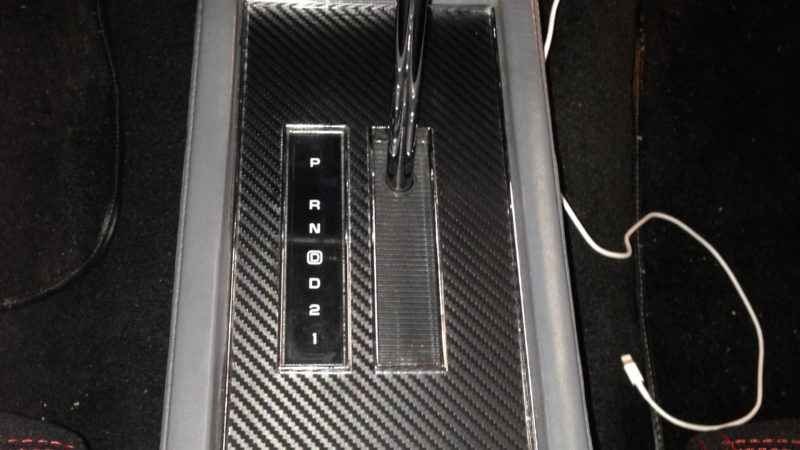

Moving further back, a 10" 3100 stall PTC torque convertor took 35 pounds off the crankshaft and allowed the engine to spin up the Precision Turbo and Engine billet turbine 5857 turbocharger. The transmission is a Boost Crew custom Stage 3 piece using CK Performance billet parts throughout. An overflow bottle was also affixed to the transmission vent to prevent spoiling the surface if the unit overheated during competition.

After discovering a broken tooth on the ring gear during an inspection in 2016, the ring and pinion were replaced with 3.73 units, and the rear axle assembly was rebuilt with Strange Engineering tapered-bearing C-Clip eliminators.

The front brakes are a Wilwood 12.88" disc setup with 6 piston Dynalite Superlite calipers. The rear brakes were converted from drum to disc a using a kit created with Wilwood GM-style calipers and rotors with a mounting plate from ScaredBird. The troublesome Powermaster electric brake booster was replaced with a Wilwood 15/16" manual master cylinder and Wilwood adjustable proportioning valve.

Suspension wise, the vehicle uses Speedtech control arms up front. The owner chose Speedtech because they offered an arm providing additional caster, but still used the conventional spring and shock setup. Custom AFCO dampers control Moog 5660 springs in the front, and Moog CC651 cargo coils in the back. A custom sway bar created using a NASCAR style 37.5" splined end hollow bar from Speedway Engineering was fabricated by the owner after he was unable to source an off-the-shelf bar with enough bar rate.

At the back, a Fayes2 Watts Link has been installed to override the factory rear roll center, which normally lies somewhere in the trunk. This greatly improved the predictability of the car. The previously ever-present prospect of snap oversteer and spins has been completely vanquished. The stock rear control arms and new OEM bushings remain because the Watts Link requires the stock four link suspension to deform slightly, or else it will bind. The rear anti-sway bar also remains original. The owner has observed other vehicles of this architecture with stiffer rear bars picking up the inside rear tire in turns. This car doesn't.

The wheels are Weld RTS-71B forged in 18x9.5 shod in Bridgestone Potenza RE71-R tires in 275/35R18, the largest fitment the owner can get under the car without cutting sheet metal.

Inside the vehicle, the stock seats were removed after the owner experienced a tilt-column failure during an event. The stock seats were not supportive enough, and the driver had to hold himself in the seat by way of the steering wheel. Not a safe situation. The stock seats were removed and replaced with NRG Sport bucket seats with much better bolstering. A Corbeau four point harness was added for autocross use. The mint condition original steering wheel was removed for safekeeping and another Grand National wheel was sourced used and sent to Dallas Custom Steering Wheels to be recovered in alcantara. The air conditioning and heat remain fully functional, as does the JVC stereo with a mix of Alpine, JL Audio, and Kicker speakers in the stock locations.

The end result has been a car with great street manners and the ability to pull 1.2g laterally on asphalt and concrete. It is competitive in regional SCCA Solo competition, routinely winning its class in its home region, and regularly earning trophies in surrounding regions.

The car has been features in Grassroots Motorsports Magazine (February, 2014, before most of the transformation took place), as well as on the GRM Facebook page during the 2016 CAM Challenge in Peru, Indiana. It also qualified for the 2018 Optima Ultimate Street Car Invitational and will be on display at SEMA in Las Vegas the week of October 29, 2018.

Build Sheet

Manufacturers

- ARP – Automotive Racing Products - Engine fasteners

- Bowler Performance - Good times!

- Wilwood Disc Brakes - Front disc brake kit

- Wilwood Disc Brakes - Master Cylinder and Proportioning Valve

Shops

Services

- Street Legal TV - Placeholder